- You are here:

- Home

- Thermal Management & Ventilation

Thermal management and ventilation

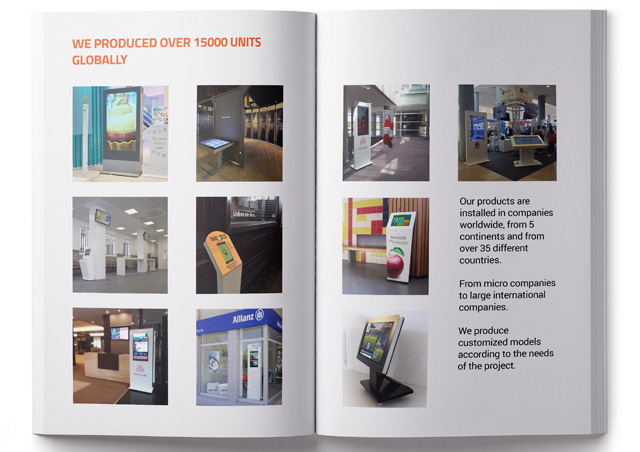

Taking into account the conditions inherent to digital billboards and multimedia kiosks, particularly for outdoor, it can be said that the key element of these systems is, besides ventilation, temperature control.

Strongly recommended, the thermal management of the equipment ensures the normal and correct functioning of all components – besides avoiding their deterioration.

PARTTEAM & OEMKIOSKS, aware of the importance of temperature and ventilation systems, seeks to ensure maximum efficiency and reliability in all its products.

Thermal Management and Ventilation for Outdoor Digital Billboards

The requirements of an internal environment are easy to understand, since there is total control of the environment and a certain stability. This makes digital billboards or indoor multimedia kiosks don't require as much care as outdoor equipment.

Therefore, outside, there are other attentions that must be taken, being the primordial element of this system the control of the temperature. Moreover, PARTTEAM & OEMKIOSKS has a proprietary system – CROXTHERM® – for thermal management and display cooling.

Thermal Management

Temperature management ensures that all system components function correctly. Through this management, stains are prevented, more specifically when the temperature on the screen surface is high; good levels of performance are guaranteed and a long life of the integrated components is ensured.

How heat slowly “kills” LEDS

Junction temperature: The junction temperature is the active region of the LED. This is where electrons jump between the two semiconductors to produce photons. A low junction temperature helps LEDs to produce more light. The junction temperature is affected by current, thermal path and ambient temperature.

A difference of 11ºC in the junction temperature makes a difference of approximately 30 thousand hours in the life of the leds.

* The values shown in this graph differ according to the display brand.

Importance of

a good Thermal Management

Although it is important to ensure that any outdoor display can withstand the weather, it is equally important to ensure that it withstands the varying temperatures of an outdoor environment.

Both cold and heat affect LCD displays. Therefore, it is important to consider thermal management, since it protects the equipment from the outside temperature, ensuring image quality, low power consumption and component conservation.

Thermal Management

is recommended

The thermal management of the equipment is strongly recommended, because:

- Prevents interruptions and malfunctions caused by overheating or cooling of electronic devices;

- Reduces costs related to the installation and maintenance of equipment;

- Increases the duration of the internal components.

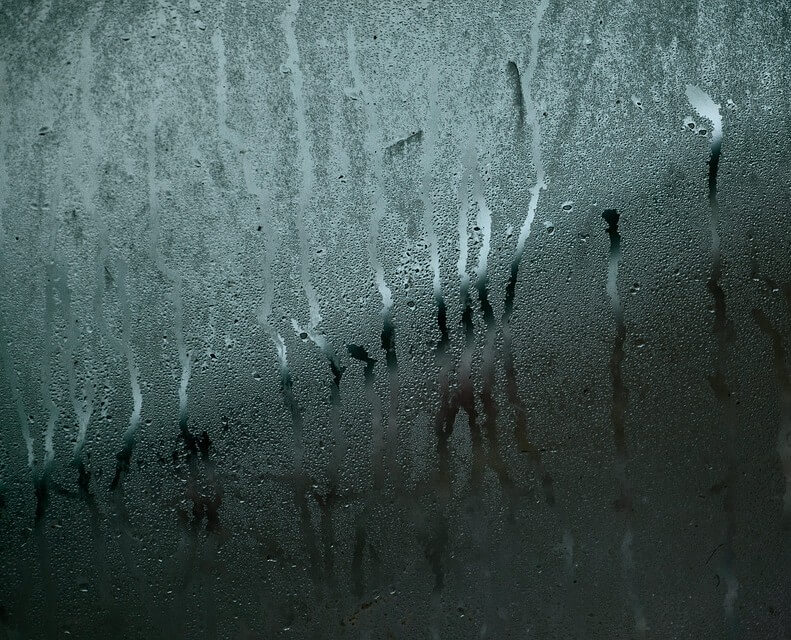

Drop in temperature causes dangerous condensation

In a structure, in case the relative humidity of the air is 80% and the temperature is 30ºC, the air will contain approximately 25 milliliters of water. If the temperature drops to 15ºC, the air will contain about 13 milliliters with the same humidity.

The other 12 milliliters condense. At first it may not seem like much, but with the natural movement of air, this amount is concentrated in the coolest parts of the equipment.

Source: pfannenberg.com

Temperature drop causes dangerous condensation

Equipment

temperatures

The equipment temperatures depend on several factors, such as:

- The amount of heat generated by the equipment components;

- The amount of heat generated by auxiliary and cooling equipment (such as fans);

- Environmental conditions (such as temperature, solar radiation and wind speed);

- The objects naturally present at the installation site (such as shade, buildings, trees, cars);

- The equipment design.

Temperature ranges

of a display

The outdoor display temperature varies between 0 and 50ºC – it is the guaranteed maintenance temperature. An ambient temperature (approximately 25ºC and involving an active cooling system) or the normal operating temperature (which varies between 10 and 40ºC) can also be used. Within this last one, heat or cold don't affect the display.

Glass protection

PARTTEAM & OEMKIOSKS sun protection foils offer several advantages throughout the year, adapting to both the exterior and interior. In addition to being able to control light, they ensure thermal optimization. In other words, they allow better insulation in winter and a significant reduction of heat in summer.

A glass covered with these sunscreen foils can prevent infrared radiation, controlling peaks of light and reducing them to a level pleasing to the human eye. This creates effective protection for the equipment.

Advantages of glass protection:

- Brightness control;

- Energy saving;

- High resistance;

- Variety of colors, which makes the equipment more sophisticated;

- Equipment protection.

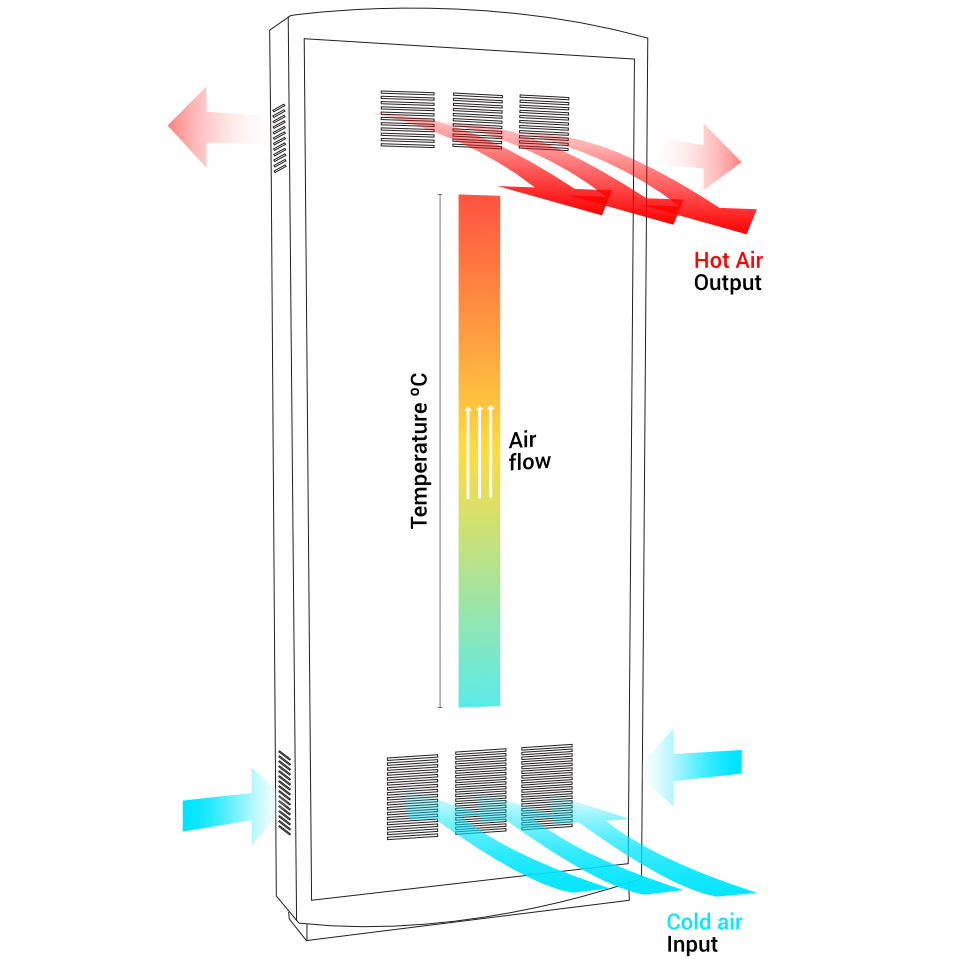

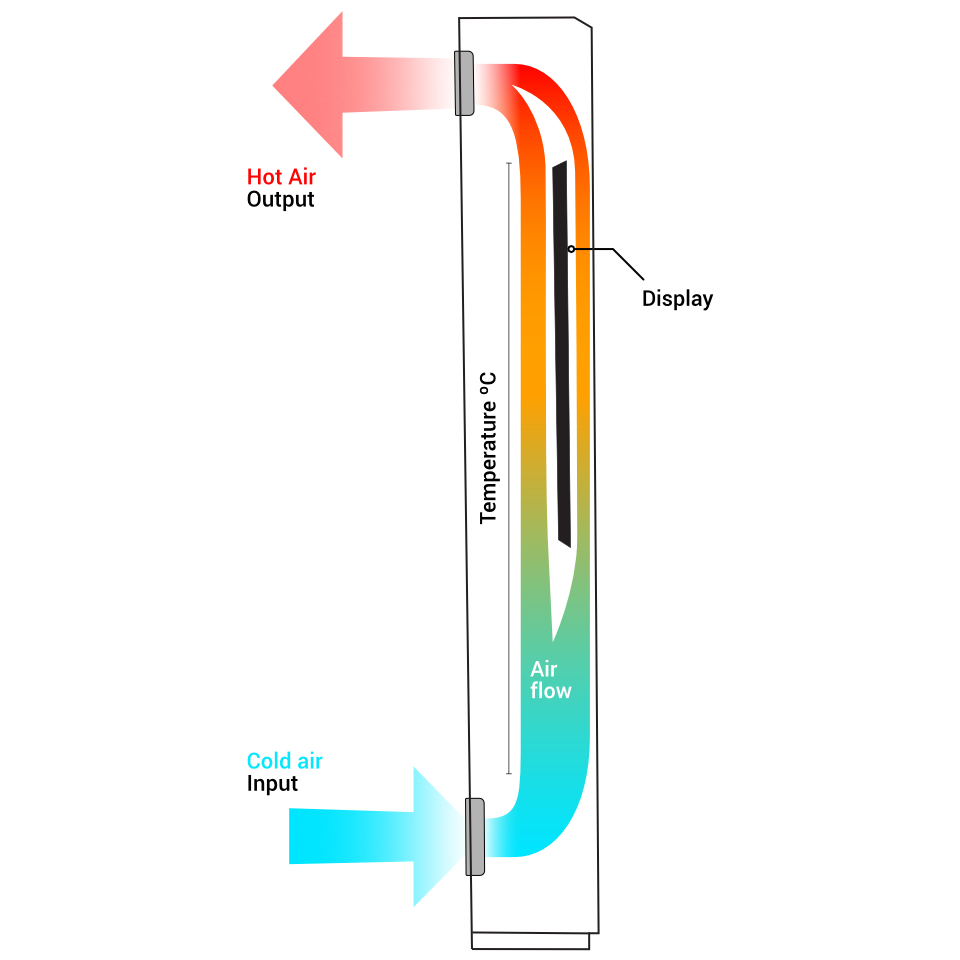

Ventilation systems

In an indoor kiosk, the ventilation makes the air circulate and it is always possible to keep the same temperature inside the kiosk. In an outdoor kiosk, the same is intended to happen, although other precautions have to be taken.

PARTTEAM & OEMKIOSKS ventilation systems ensure maximum efficiency and reliability, even at extreme temperatures and large fluctuations.

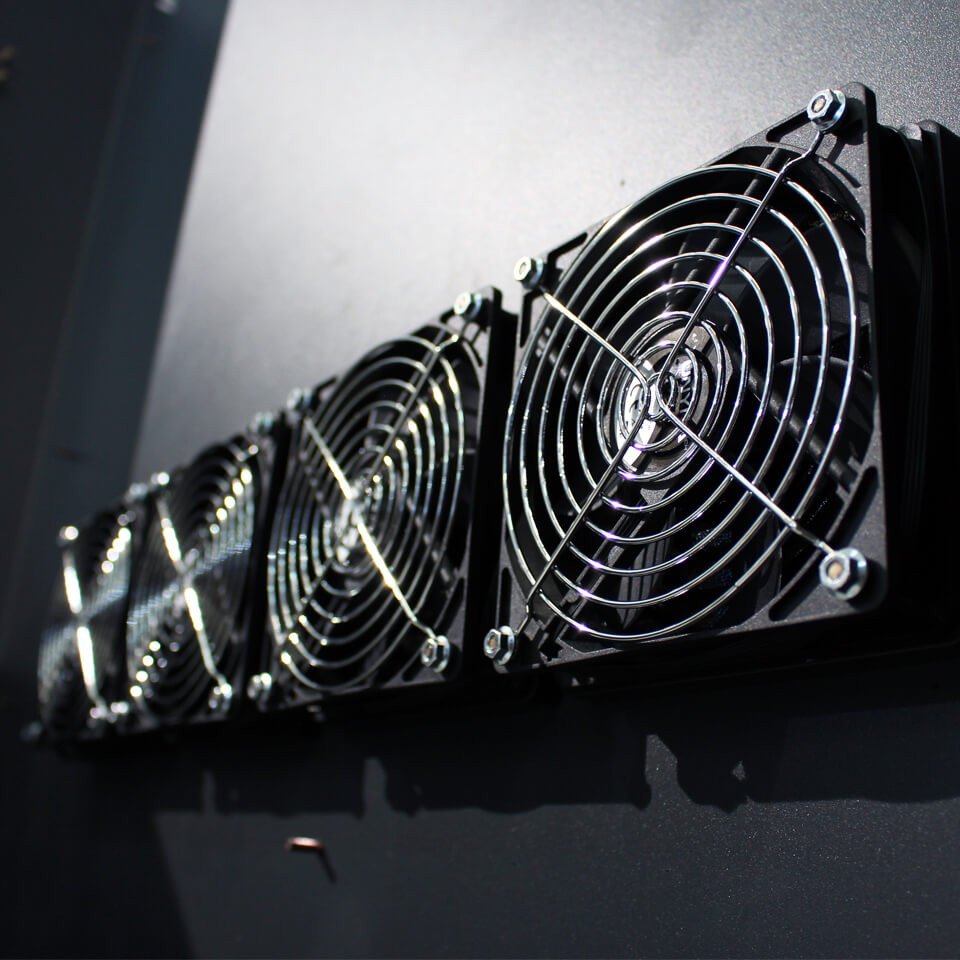

Fans

Faced with the fact that outdoor kiosks are subject to adverse environmental conditions that can affect the performance of sensitive electronic components – from extreme temperatures to humidity and dust –, this equipment must be prepared to maintain its internal temperatures, regardless of climate.

For indoor kiosks, extreme temperatures are less risky, so the ambient temperature tends to remain constant. Often, these kiosks maintain their temperature through convection ventilation. However, if the structure is overheated, a fan can be used to dissipate the heat from the electronic components and the upper ventilation of the kiosk.

Importance

of ventilation systems

The ventilation systems cool the components of an equipment, guaranteeing the quality of the air that circulates and preventing the infiltration of pollutant gases, bacteria and humidity.

Therefore, these systems are vital for the normal operation of the equipment and its components.

How do they work?

Ventilation systems work in several ways. There are several options to be considered, because if a display gets too hot, for example, its liquid crystals can be permanently damaged. But there are ways to control the temperature and air circulation:

- Use the outside air to cool the display components, avoiding that the inside temperature gets too hot;

- Use the advanced thermal management of the display, so that the internal temperature is not too high;

- Use the air conditioning inside the digital billboard, which works automatically with regard to temperature.

This effect is controlled in all projects, studying the location and positioning of the equipment in order to analyze the position of the sun during the day and to understand if it will harm its use.

Airflow

velocity

The measurement of the airflow velocity allows to know if the fans are in full operation and if the air filters are obstructed with dust or not.

For a good functioning of our kiosks, an efficient and correctly tested ventilation is essential. Perfect air circulation must be guaranteed at all times. For this reason, air inlet and outlet flows must be measured at regular intervals.

Our tests with flow rate meters are ideal for obtaining this guarantee.

Air Conditioning

One of the most effective ways to avoid the heating of a digital signage equipment is through the use of air conditioning, which regulates the air temperature according to the billboard's temperature.

When the billboard is equipped with air conditioning, it ends up not having external ventilation, so that the air conditioning has the maximum efficiency.

In this case, if there is no “connection” with the exterior – other than through air conditioning – the entrance of humidity, dust and water is avoided.

Besides, the equipment can be completely sealed with IP65 protections, safeguarding the structure.

Extreme cooling is neither necessary nor appropriate

Studies have shown that electronic components tend to last longer if temperatures remain low. But there are other factors in the structure that must be considered, such as the risk of condensation and energy costs.

In fact, the important thing is to maintain a stable temperature and not necessarily low in the equipment. The ideal recommended temperature is approximately 25°C, protecting the components, minimizing the risk of condensation and reducing energy costs.

Source: pfannenberg.com

Peltier effect

Thermoelectric cooling uses the Peltier effect to transfer heat from one side of the device to the other. It can be used for heating or cooling (although, in practice, cooling is the main application).

Advantages of the Peltier Effect:

- It has no moving mechanical parts, so they are silent;

- It is indicated for the stabilization of the temperature;

- It doesn't use pollutants gases;

- It has a small size and a flexible format;

- It doesn't need maintenance and can work in any position.

Equipment

covering

In order to combat the high temperatures in some locations, PARTTEAM & OEMKIOSKS kiosks are covered with thermal insulation. That is, they are prepared to allow a lower heat exchange, so that the external heat is not felt inside the kiosk and the cooling system has a higher efficiency.

This insulation also reduces the heat exchange between the external environment and the internal environment, which ensures a more stable and healthy temperature for the equipment.

Through this action, it is also possible to have significant savings in air conditioning costs, contributing to a more eco-efficient kiosk.

PARTTEAM & OEMKIOSKS internal tests

At PARTTEAM & OEMKIOSKS, the equipment is designed with intensive quality testing. Firstly, a study is carried out taking into account the heat dissipation of the components and the place where they will be installed – analyzing the average ambient temperature and sun exposure.

On the factory floor, the kiosks are placed inside a greenhouse with projected heat sources – where they stay for several hours –, and this test is monitored through data collected by sensors scattered over several areas of the kiosk. The objective is to understand if the heat is becoming concentrated and putting in question the functioning of some component.

Tests are also performed with cooling and ventilation systems to see if the correct system is being used. If necessary, a readjustment is made during the assembly process to ensure the proper functioning of the equipment.

Contact Us

Need to know more informations about this solution? That's the reason we are here for.

If you have questions and are interested about this solution, don't be afraid to ask. We have a comercial team ready to answer your questions!